Details

Deep Well Heating Furnace Overview

The well type furnace mainly comprises a furnace body frame, a furnace bottom frame, a furnace lining, a furnace cover, a heating element, and an electric control.

1, the furnace frame

The side plate of the furnace is made of carbon steel plate with δ=5mm and channel steel, and it is proved by practice that the integral structure has good steel property, high strength and long-term use without deformation.

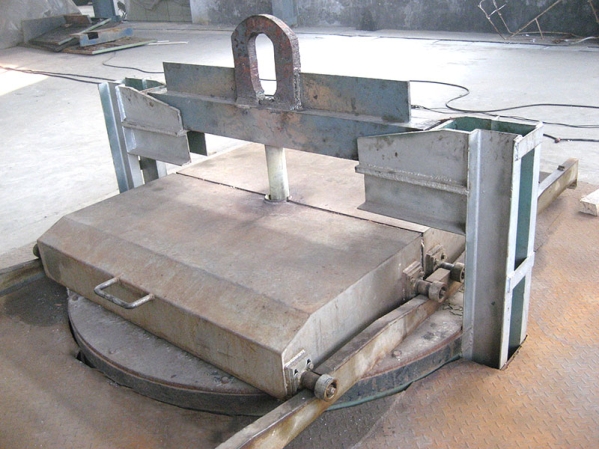

2, the bottom frame

The bottom frame is welded by 12# steel and steel plate to support the bottom of the furnace and the rotating mechanism, and is welded to the furnace body during installation.

3, furnace lining

3.1 The side wall of the furnace body is composed of refractory fan-shaped clay bricks, wire bricks, diatomaceous earth bricks, vermiculite powder and aluminum silicate fiber felt. The total thickness is ≥350mm.

3.2 Bottom: A composite structure consisting of diatomite brick, refractory clay brick and asbestos board.

3.3 Furnace port: It consists of heavy clay brick, diatomite brick and asbestos board. It is mainly used to prevent the workpiece from lifting and impact on the furnace mouth during the lifting process.

4, the furnace cover

The furnace cover and lifting mechanism are composed of a furnace cover frame, a furnace lining, lifting and the like.

4.1 The furnace cover is welded by frame steel plate and section steel, which has certain rigidity and stability.

4.2 Furnace lining: It is made of high-quality aluminum silicate refractory fiber. This structure has the advantages of light weight and small heat storage.

5, heating elements

The heating element is uniformly arranged on the wire brick around the furnace by the 0Cr25A15 high-temperature spiral alloy wire. In order to prevent the resistance wire from falling off, the porcelain cap or the heat-resistant steel nail is inserted into the reserved groove of the wire brick, so that it is not easy to fall off, and the guarantee is ensured. Operational safety.

6, electrical and control parts

The temperature control adopts Japanese Fuji intelligent instrument and PID adjustment. The 4-20mA logic current output mode is used to trigger the two-way thyristor (thyristor) through the thyristor power regulator, and the power output percentage of the thyristor is changed to achieve the temperature control purpose. The thyristor is made of domestic high-quality brand products and has a good heat dissipation device. The trigger mode of the thyristor is zero-crossing triggering. The thyristor power regulator is selected from Shanghai Guolong products. The electric heating circuit is provided with an isolating switch. In addition to the open circuit detection, short circuit and overload protection, the control system is also equipped with a redundant control temperature system, that is, a large AC contactor is added on the heating main circuit, and an alarm is used for the temperature control table. The contact is controlled by a small intermediate relay, and the thyristor is controlled during normal operation. Once a phase of the thyristor is broken down, the temperature control table will automatically switch to the redundant temperature control system immediately to achieve the non-stop furnace. The temperature can continue to be controlled to ensure the qualification of the workpiece in the furnace. For the heating element, an ammeter is added to each phase on the heating main circuit to visually reflect the operating state of the heating element.

The temperature recording adopts the paperless recorder, which has the advantages of high life span, intuitive display, convenient storage and printing, long recording period and convenient maintenance.