Details

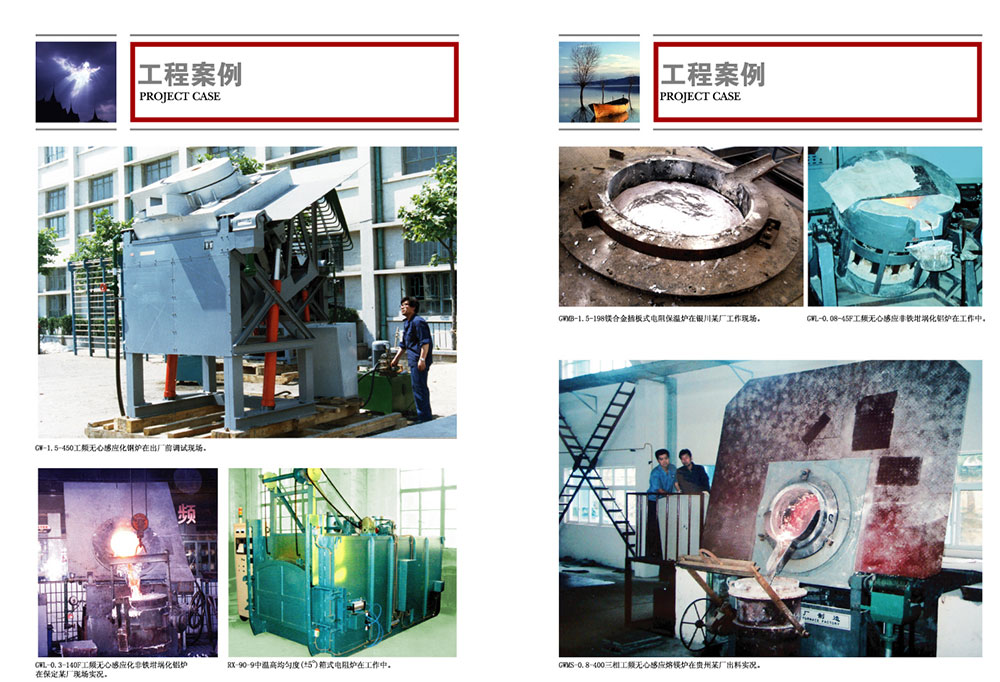

The GWMS and QRLB series of three-phase unpowered power frequency induction magnesium furnaces and holding furnaces developed and produced by our company have a rated capacity of 0.6~1.5t. They are the first in China and are exclusively produced. The first products have been available since the 1990s. Since more than ten years of practice, the product has excellent performance and reliable quality, and is an ideal melting equipment for magnesium alloy die casting and casting.

Features:

1, the melting speed is fast, the fastest speed is 20min per furnace

2. The input power can be continuously adjusted according to the process and can be carried out at any point.

3. There is no hump in the liquid surface during the melting process, and the metal burns less, especially suitable for melting flammable light metals such as magnesium alloy.

4. Input current balance, the three-phase current unbalance is less than 10%.

5, 坩埚 long life, statistical life is more than 500 heats.

6. The equipment is easy to operate, and the electric furnace can be operated after short-term training.

7. It has the function of melting process setting, and the electric furnace can run according to the set temperature process.

8. The electric furnace is a hydraulic tilting furnace, which has the characteristics of fixed point casting and stable casting.

|

rated power

|

360KW

|

670KW

|

|

power

|

Three phase 380V 50HZ

|

Three phase 380V 50HZ

|

|

Crucible Capacity

|

600Kg

|

1500Kg

|

|

Melting rate

|

1000Kg/t

|

1500Kg/t

|

|

Operating temperature

|

780℃

|

780℃

|

|

Power consumption

|

450KWH/t

|

446KWH/t

|

|

Three-phase current imbalance

|

<10%

|

<8%

|

Main technical parameters of GWMS three-phase uncentered power frequency induction magnesium furnace

|

model

|

Rated Capacity

(t)

|

rated power

(kw)

|

Rated voltage(V)

|

Melting rate(t/h)

|

Power consumption(kw.h/t)

|

Operating temperature(℃)

|

Cooling water consumption

(t/h)

|

Furnace weight

(t)

|

Dimensions(L×W×H)(mm)

|

|

GWMS-0.6-360

|

0.6

|

360

|

380

|

0.8

|

450

|

750

|

8

|

5.0

|

3000×2305×2815

|

|

GWMS-0.8-400

|

0.8

|

400

|

380

|

0.9

|

450

|

750

|

10

|

6.0

|

3080×2385×2815

|

|

GWMS-1.0-450

|

1.0

|

450

|

380

|

1.0

|

450

|

750

|

10

|

8.0

|

3400×2700×3400

|

|

GWMS-1.2-540

|

1.2

|

540

|

380

|

1.2

|

450

|

750

|

12

|

10.0

|

3500×3900×3600

|

|

GWMS-1.5-670

|

1.5

|

670

|

380

|

1.5

|

446

|

750

|

15

|

12.0

|

3800×4100×4200

|

|

GWMS-2.0-880

|

2.0

|

880

|

500

|

2.0

|

440

|

750

|

16

|

16.0

|

4200×4850×4900

|

|

GWMS-3.0-1300

|

3.0

|

1300

|

750

|

3.0

|

435

|

750

|

25

|

20.0

|

4400×5200×5200

|

|

GWMS-3.0-2150

|

3.0

|

2150

|

750

|

3.0

|

430

|

750

|

30

|

22.0

|

4400×5200×5200

|